Carbon Dioxide Laser Tester For Carbon Dioxide Content Detection

Purpose

To realize the continuous online quantitative detection of CO2 concentration, the instrument has the characteristics of high accuracy, fast response, no calibration, no interference from water vapor and other gases, etc. It has a good application in the continuous monitoring of carbon dioxide emission of flue gas in thermal power plants, metallurgy and other industrial fields

Technical parameter

Use ambient conditions operating voltage: AC220V± 10% 50~60Hz Operating temperature: -10℃ ~ + 50℃ storage temperature: -30℃ ~ + 85℃ relative humidity: not more than 90% atmospheric pressure: 860 hPa ~ 10 60 hPa 13.2 Light source infrared tunable semiconductor laser

Measurement of gas component carbon dioxide

measurement range (0-25)

resolution 110-

Value error: ± 1% (relative error) or ± 0.25% (absolute error) of the full range; The time until the display value rises to 90% of the stable value, T90, is not greater than 20 seconds

Preheating time: less than 15 minutes

Measurement mode in-situ continuous online monitoring

output interface optional

mA current ring, RS485 or RJ 45 network port

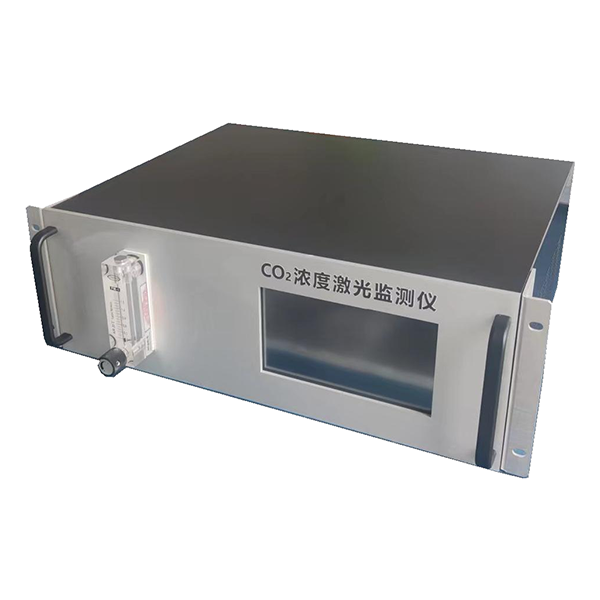

overall size 483mm 350mm 155mm (long depth and high)

Weight: 6.5kg

Composition and function of the instruments

The instrument includes laser control unit, constant temperature and long-range optical machine components, touch screen, low noise spectrum acquisition and analysis unit, thermostatic control unit, data isolation output unit, AC-DC power supply, etc.2 3 touch screen real-time display carbon dioxide concentration data, graph and equipment status information, easy and intuitive operation, can through 4~20mA current ring, RS485 or RJ 45 port for remote data transmission, instrument internal heating function, can effectively prevent water vapor condensation, and has the function of automatic lock, ensure long-term working laser wavelength does not drift

Operation and maintenance

Safety description The installation position of the instrument should belong to the non-explosion-proof safety area, and the gas entering the instrument should be treated before water removal and dust removal, etc. Before use, please correctly connect 220V AC, and ensure good grounding.

Operation instructions

prepare and use a) put the instrument smoothly, check whether the power cord, intake pipe, exhaust pipe and data line are correctly connected, confirm that the connection is secure, without leakage; b) adjust the intake flow to about 500 SCCM through the flow regulator; c) turn on the power switch, start the preheating waiting procedure after the instrument starts, the display will appear corresponding prompt, the preheating time will be automatically adjusted according to the status of the instrument, no more than 15 minutes;

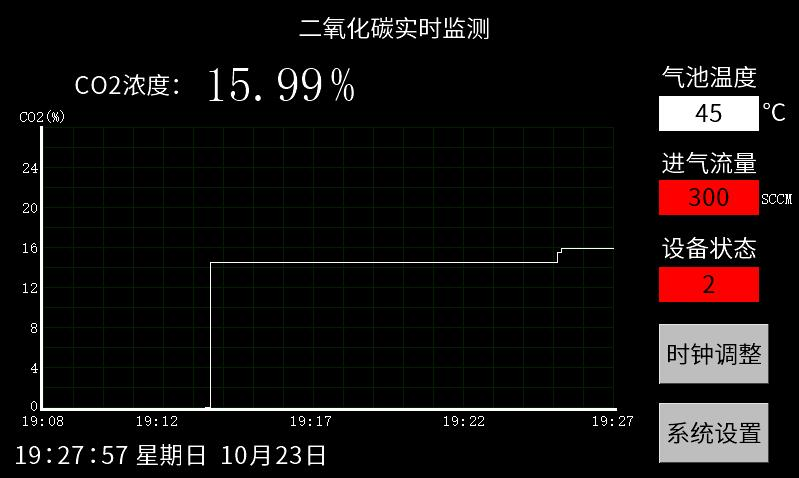

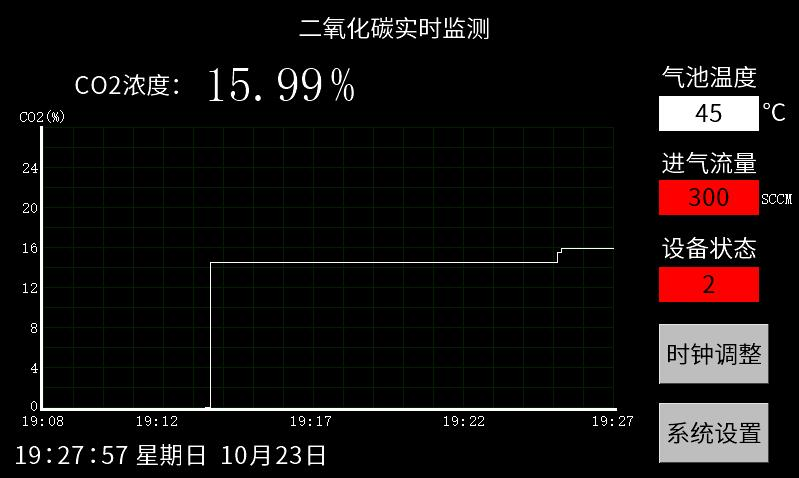

,the main interface and the operating instrument are shown in Figure

ncluding real-time data of CO2 concentration, the last 20-minute signal interface, power input, network interface inlet cooling fan, data curve of power switch exhaust port 5, air tank temperature, intake flow, equipment status, real-time clock, etc

Under the condition of normal intake flow, the CO2 concentration can be automatically detected in real time without manual intervention. Under normal condition, the air tank temperature should be stable at 45℃, and the display box is white. When the air tank temperature is less than 44℃ or more than 46℃, the display box turns red; when the air intake flow should be adjusted to about 500 SCCM, when the intake flow is less than 300 SCCM or greater than 700 SCCM, the display box becomes red; when the equipment status code is 0 indicates that the instrument is in the best working condition, and the state code is not 0, the instrument has one or more abnormalities; the abnormal code is defined in the table below

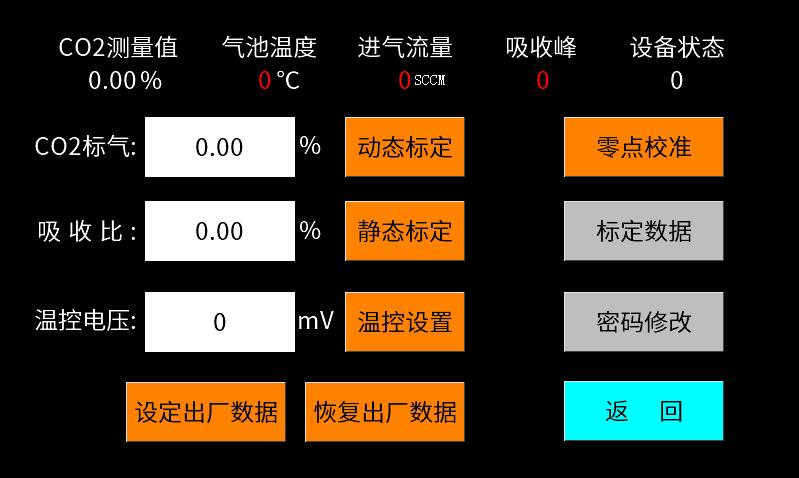

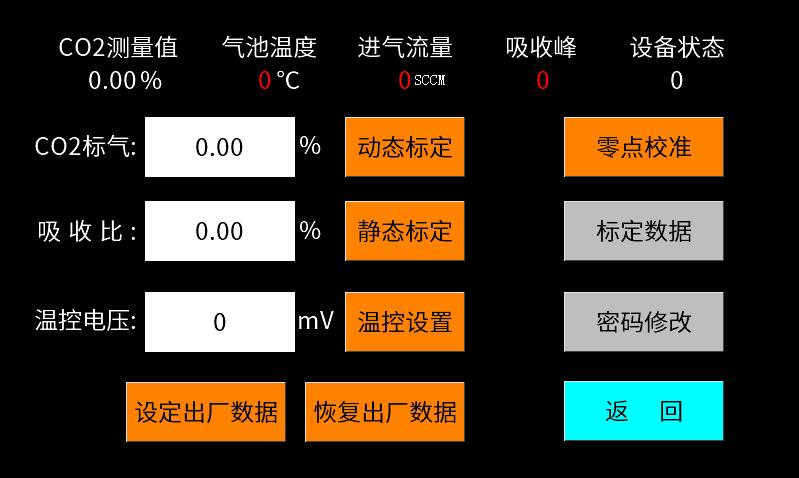

Click the "Clock Adjustment" button to set the date and time; when the instrument needs to adjust the relevant important parameters, you can enter the setting interface through the "System, Settings" button, and the setting interface requires a password, as shown in Figure 5.2

The instrument is precision optical equipment, the use process should be light light, to prevent falling, collision and other situations, and pay attention to waterproof and moisture-proof. When using the touch screen, do not use sharp objects, and use the appropriate force to prevent accidental damage to the screen. When cleaning the screen, be careful not to liquid into the instrument from the edge of the screen, causing damage to the instrument.